Esmil Process Systems founded in 1975 has over 40 years’ experience in the field of industrial effluent treatment achieving recognition for process/systems solutions including the prestigious “Queens Award for Environmental Achievement” and “DTI best supplier”.

Esmil are able to provide cost efficient, environmentally friendly waste water treatment solutions using a combination of technologies including:

- Pretreatment;

- Ultrafiltration;

- Nanofiltration;

- Reverse osmosis;

- Membrane Bio-Reactors;

- VSEP (Vibratory Shear Enhanced Process) non fouling membrane systems;

- Sludge dewatering.

Esmil with our technology partners have conducted much research and have acquired vast experience in the field of digestate treatment. From bench scale studies to full scale plant operations, Esmil offer bespoke digestate waste water treatment for all AD feed types using state of the art membrane separation and dewatering processes and systems.

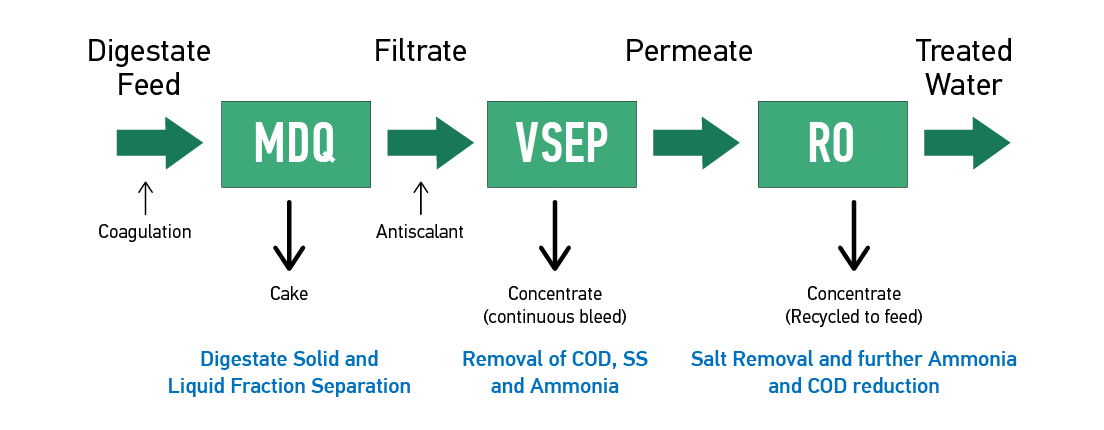

Esmil’s digestate treatment system consists of 3-unit processes and is able to produce a dry solid cake and a recovered water (permeate) suitable for process reuse or disposal. Esmil can even offer a Zero Liquid Discharge digestate treatment solution if sufficient waste exhaust heat from the CHE units is available.

The first stage in the digestate treatment process is digestate dewatering. Dewatering is achieved through various physico-chemical processes and seeks to remove as much of the TSS from the whole digestate as possible.

Multi-disc screw press MDQ

The second stage of Esmil’s digestate treatment process utilises proprietary technology based on a fouling resistant vibrating membrane system or VSEP (Vibratory Shear Enhanced Processing).

High levels of suspended and dissolved solids in the digestate cause serious issues for standard membrane systems as they are highly susceptible to fouling and scaling. VSEP technology vibrates the membrane pack causing high shear forces at the membrane/fluid interface, greatly reducing the risk of fouling.

The high shear process keeps the membrane pores exposed allowing for maximum permeation of water. Contaminants and a fraction of the water are rejected by the membrane and remain on the concentrate side. This ‘concentrate’ will contain the majority of nutrients from the digestate liquor fraction and can be marketed as a high nutrient liquid fertilizer in the agricultural/horticultural markets. The concentrate has a high concentration of TAN which is readily taken up by plants with no emission risks in transport or application.

Esmil’s final stage of digestate treatment utilises spiral-wound reverse osmosis membrane technology. This process polishes the permeate (treated water) from the VSEP units. Residual COD, ammonium salts and TDS are efficiently removed at this stage (typically 99% strip) and this concentrate stream is recycled to the VSEP feed to improve overall water recovery and improve the value of the VSEP concentrate stream.

Spiral Membrane System

The final permeate produced at this stage is either recycled back into process operations (dilution, plant washing & cleaning or boiler feed water) or discharged to a watercourse.

The overall process represents a revolutionary method for digestate disposal. Instead of being a cost, digestate is valorized representing a significant change in the operating costs of the AD operation. Typically, for every 1000 tons of digestate produced, between 650 and 700 tons of clean water are recovered (displacing bought in town/municipal make-up water). This water can also be discharged safely to water course without incurring transport/spreading costs.

Between 300 and 350 tons of concentrated liquid fertilizer are recovered which may either be directly marketed (trucking off cost reduced by 2/3 compared to whole digestate), or dried to produce a chemical fertilizer equivalent. The concentrate now becomes a positive revenue stream for the AD operation.

VSEP System

VSEP System