Introduction

Esmil Process Systems were tasked with providing a process solution to reduce microbiological loading and overall fat concentration in a large skimmed milk line. The client was particularly interested in low temperature milk preservation systems which ensured effective reduction/elimination of microbes in the final skimmed milk thereby reducing milk spoilage potential.

Another important consideration was the maintenance of the milk’s organo-leptic qualities post treatment. Process determinands of primary concern to the client was the maximal removal of bacteria as measured by CFUml-1 whilst minimising the rejected fats content.

Figure 1 – MF Membrane Skid

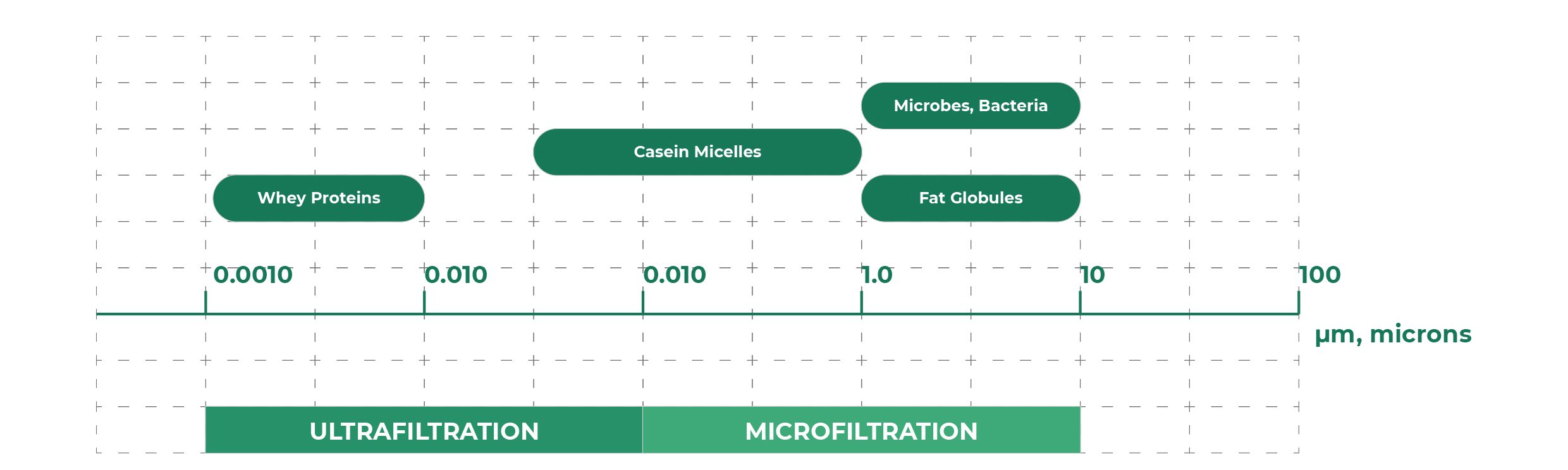

The relative dimensions of the process species under consideration are depicted in Figure 2.

Figure 2 – Relative species dimensions for milk

Process

Previous experience guided the selection process whereby a membrane configuration allowing high cross flow velocities (> 7.0 ms-1) with low trans membrane pressure drops (ΔP < 50 kPa) would allow for high retention of micro-organisms whilst minimising the loss of fats during the process. The primary advantage of this system is that it is conducted at low temperature (35 – 45°C) which minimizes the impact of separation on the organo-leptic qualities of the final product.

Case History

Skimmed milk (i.e., the milk remaining after centrifuging the whole milk stream to recover cream) is treated through 2 passes of Microfiltration membranes to achieve the aim of reducing the microbial load in the remaining milk. This allows the producer options in terms of extended shelf life (ESL) products.

Typical results and process data are tabulated below.

Results

Table 1 - Skimmed milk microfiltration process data

| Parameter [units] | Pore Φ, microns | Flux, J lm-2h-1 | Δ P, kPa | VRF x | Process temperature °C |

|---|---|---|---|---|---|

| First Pass | 1.30 | 500 - 700 | 40 - 50 | 20 | 42 - 50 |

| Second Pass | 1.30 | 450 - 600 | 40 - 50 | 10 | 37 - 45 |

Skimmed milk process determinands after microfiltration

Table 2 - Skimmed milk microfiltration determinands

| Parameter [units] | Fat globule reduction, % | Microbial load, CFU ml-1 |

|---|---|---|

| Before microfiltration | NA | 230 - 500 |

| After microfiltration | 0,40 – 0,45 | 10 - 40 |

It may be seen that the process designed and implemented by Esmil Process Systems yielded a 96% reduction in microbial loading of the final skimmed milk, with an overall loss of 0,4 – 0,45% of the original feed fat concentration.

After processing, both membrane sets were easily cleaned, regaining initial flux values after 12 hours run and no impact on membrane integrity was discerned.

Conclusions

The treatment of skimmed milk with a bespoke Esmil microfiltration membrane system successfully delivered biologically stable product with ESL possibilities, whilst maintaining the original organo-leptic properties of the original milk.