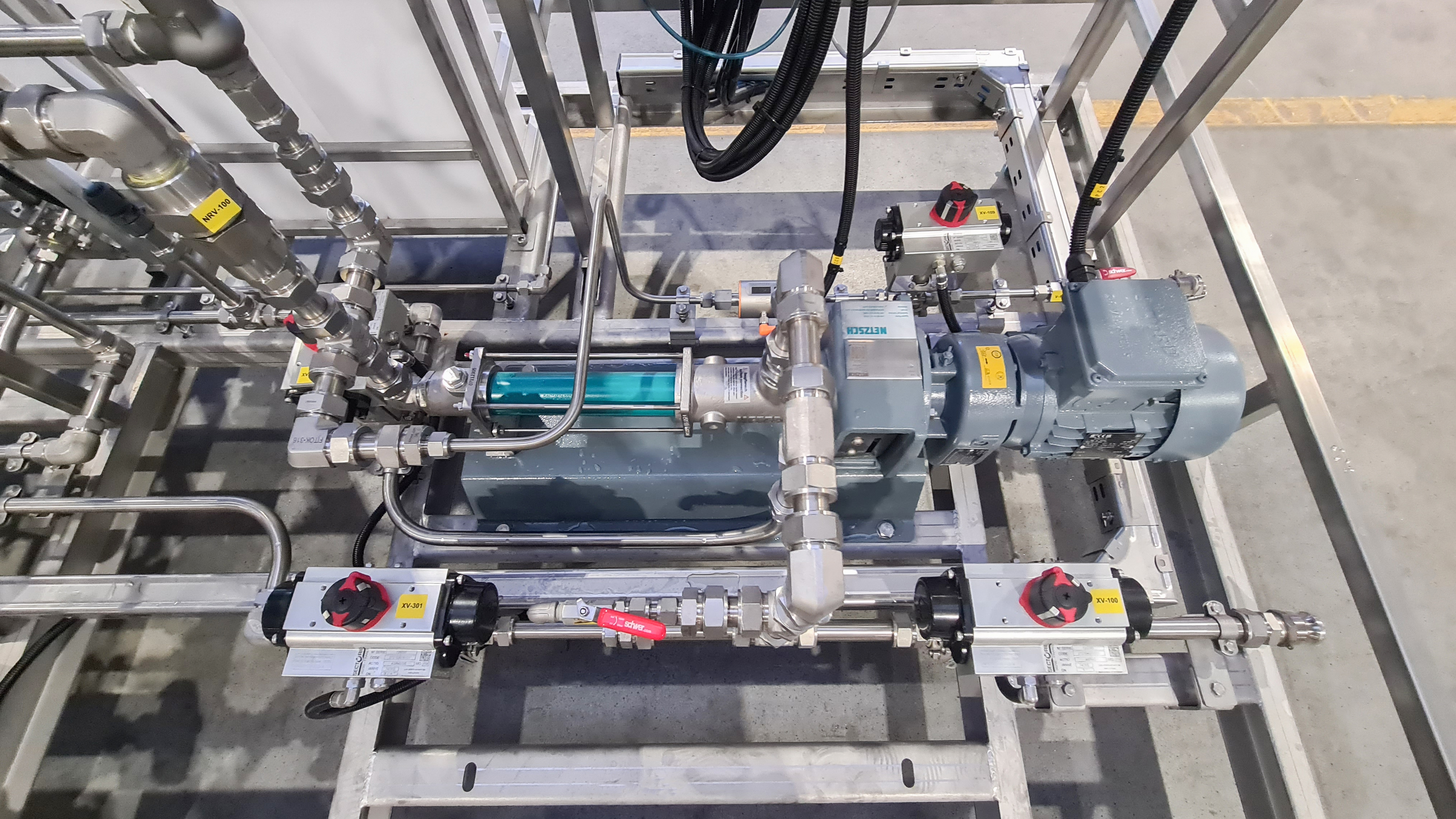

Esmil Process Systems has recently reached a major milestone in treatment technology with the successful deployment of our custom membrane filtration skid, which operates in dead-end filtration mode. This advanced system is designed in strict compliance with Regulation 31, which governs the use of materials in contact with drinking water, ensuring safety and quality from source to tap. Our dedication to these high standards is showcased by our choice of AISI 316 stainless steel for everything from the skid pipework to our custom-designed membrane housing, noted for its cost-effectiveness, superior corrosion resistance, and durability.

This choice of material is crucial for maintaining the purity of treated water and extending the lifespan of the system. By incorporating Regulation 31-compliant materials and designs, we not only demonstrate our commitment to public health and safety but also establish our skid as a benchmark for regulatory adherence in the water treatment industry.

Developed to demonstrate the capabilities of ceramic Ultrafiltration (UF) membranes, our system is designed for both research purposes and pilot-scale testing. It offers exceptional flexibility which is vital for advancing water treatment solutions. The skid combines the robustness of ceramic membranes with inline coagulation to enhance the removal of contaminants, effectively managing suspended solids, organics, and colloidal particles. Additionally, it achieves high hydraulic recovery rates while maintaining energy efficiency.

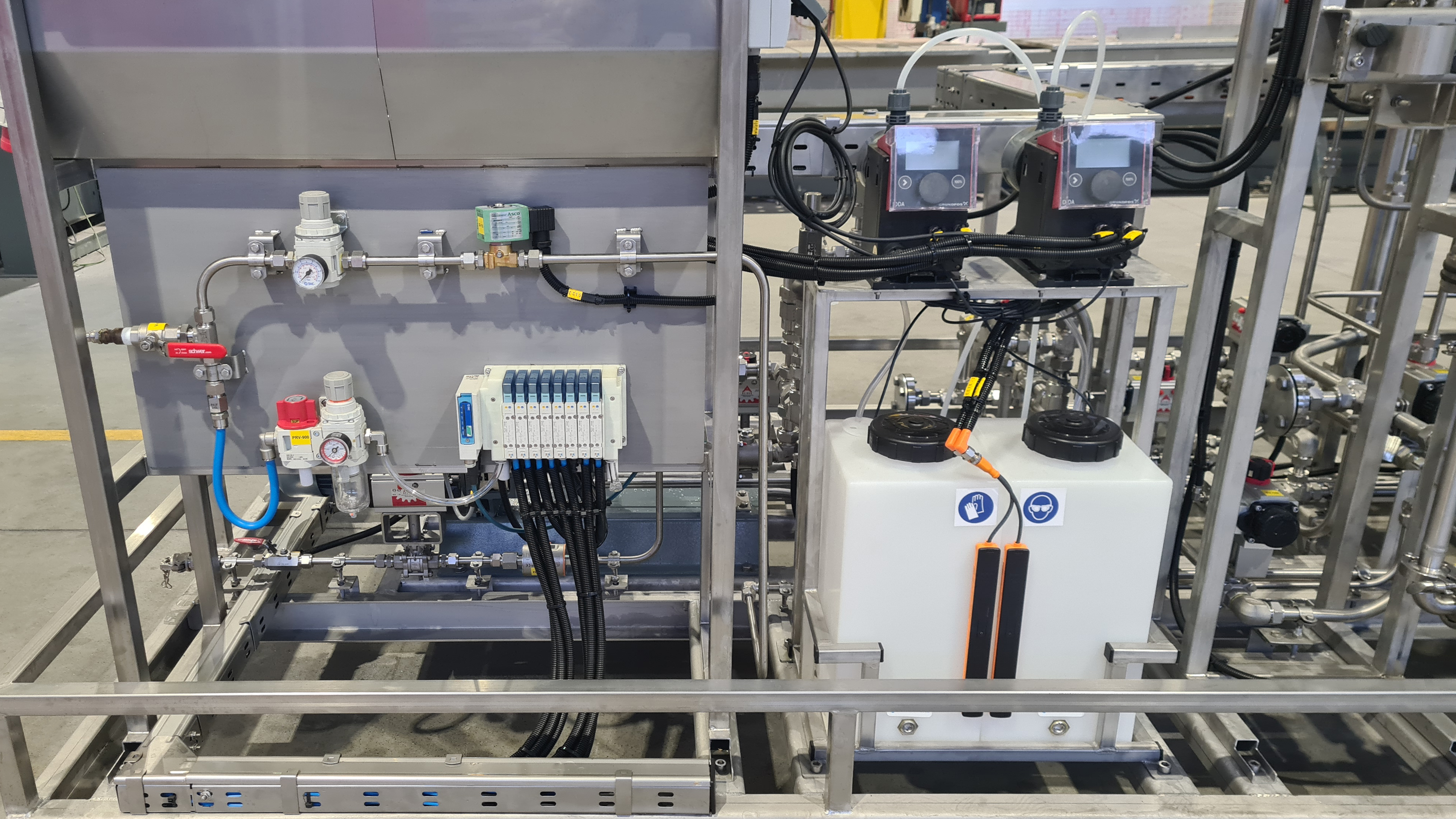

To optimise membrane performance, our system includes an air scouring process—a highly effective cleaning mechanism that uses pressurised air to dislodge fouling and maintain optimal filtration efficiency. This feature minimises chemical use, reduces cleaning frequency, and prolongs membrane life.

Our system also features automated Chemical Enhanced Backwash (CEB) and Cleaning in Place (CIP) capabilities, utilising strategic applications of sodium hypochlorite, acid, and caustic solutions to remove organic fouling, inorganic scaling, and stubborn deposits. These advanced cleaning processes ensure consistent system performance with minimal maintenance downtime.

The skid’s integrated automation ensures reliable performance across all operations. Its compact, skid-mounted design enhances transportability, ease of installation, and scalability, making it ideal for both testing and industrial-scale applications.

Esmil’s approach has proven to be a dependable solution for modern water treatment challenges, showcasing the effectiveness of ceramic membranes and automated filtration processes.