Esmil Process Systems recently conducted a comprehensive laboratory study to recover the monomers from the liquor generated in biorecycling by enzymatic process for the plastic waste. The primary objective was to separate monomers from the waste stream, which contained high concentrations of salts, particularly sodium chloride (NaCl) and sodium sulphate (Na₂SO₄). Our engineers carefully selected and applied an appropriate combination of Reverse Osmosis (RO) and Nano Filtration (NF) membrane technologies to reclaim valuable monomers for reuse.

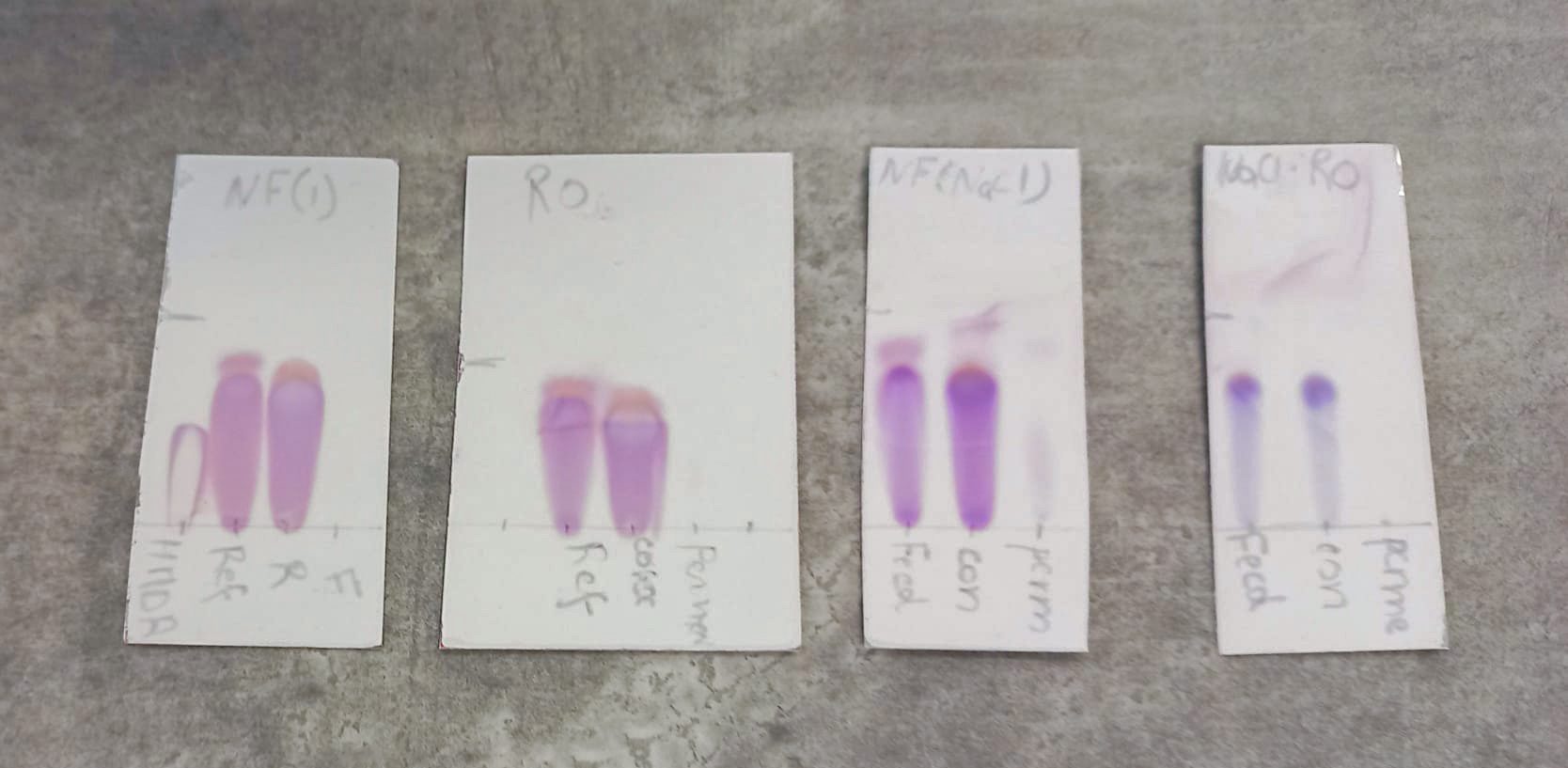

To prove the efficiency of the process, a thin layer chromatography (TLC) was employed. The TLC plates revealed the separation efficiency, with distinct spots representing different compounds in the feed, concentrate, and permeate following each filtration stage. The results confirmed the effectiveness of the treatment in selectively separating and recovering different compounds. Consequently, the economic efficiency of the plastic fabrication process and the plant’s sustainability can now be significantly enhanced.