Esmil Process Systems have gained vast experience in the field of Anaerobic Digestate treatment. From bench scale studies to on site pilot plant trials through to full scale plant supply, Esmil will offer state-of-the-art solid-liquid phase separation using membrane processes.

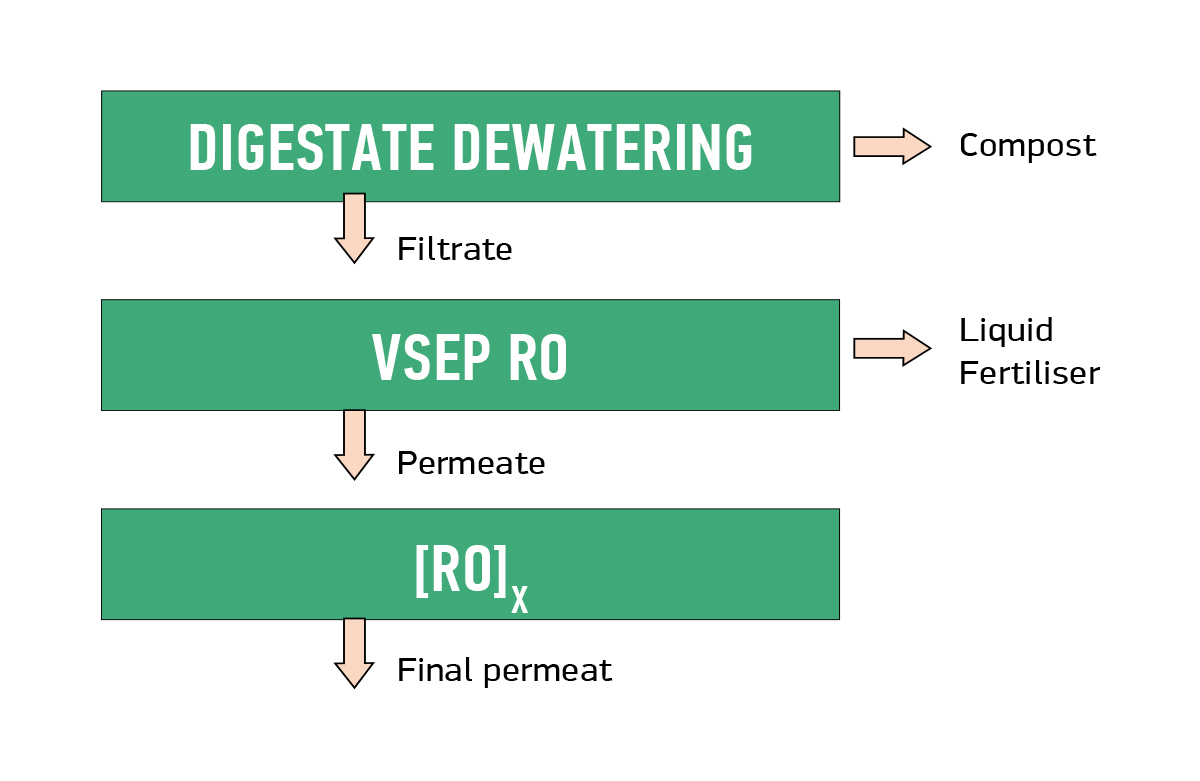

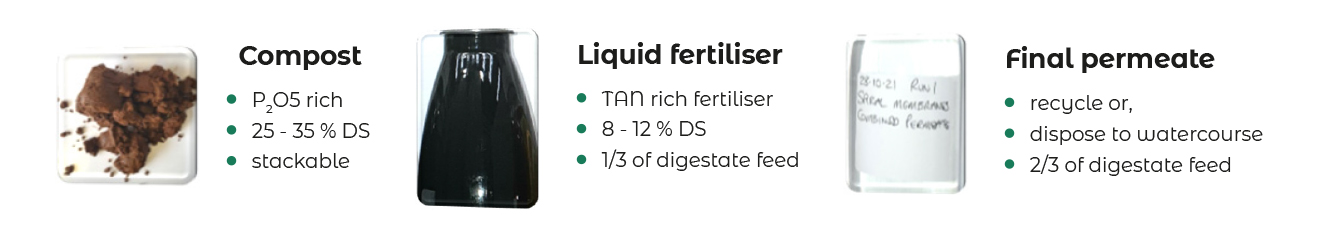

Using integrated Esmil system packages, the AD operator can now convert digestate into 3 valuable process outputs. Nearly 2/3 of the digestate is recovered as pure water which can be recycled or safely disposed to watercourse. The separated solids are available as a stackable, phosphate rich compost which is both valuable and marketable. The rest of the liquid presents as a nitrogen rich super fertiliser which is in demand in the agricultural sector.

Application of this treatment system eliminates or significantly reduces digestate truck off costs and spreading costs are eliminated. Zero Liquid Discharge digestate treatment is possible on sites where there is waste heat available.

Process Description

ESMIL DIGESTATE TREATMENT PRODUCT STREAMS

Esmil Capability

- In house laboratory analysis to prove the design concept and product stream quality to the client

- Bespoke design for each product stream

- Site pilot plant trials to confirm design data & provide confidence to the client about the system design

- Integrated system design for a fully automated treatment system with little operator involvement

- Small system footprint easily incorporated with existing plant

- Very low power requirement

- Applicable to all AD feed sources including manures, crop wastes, mixed food waste, energy crops and slurries