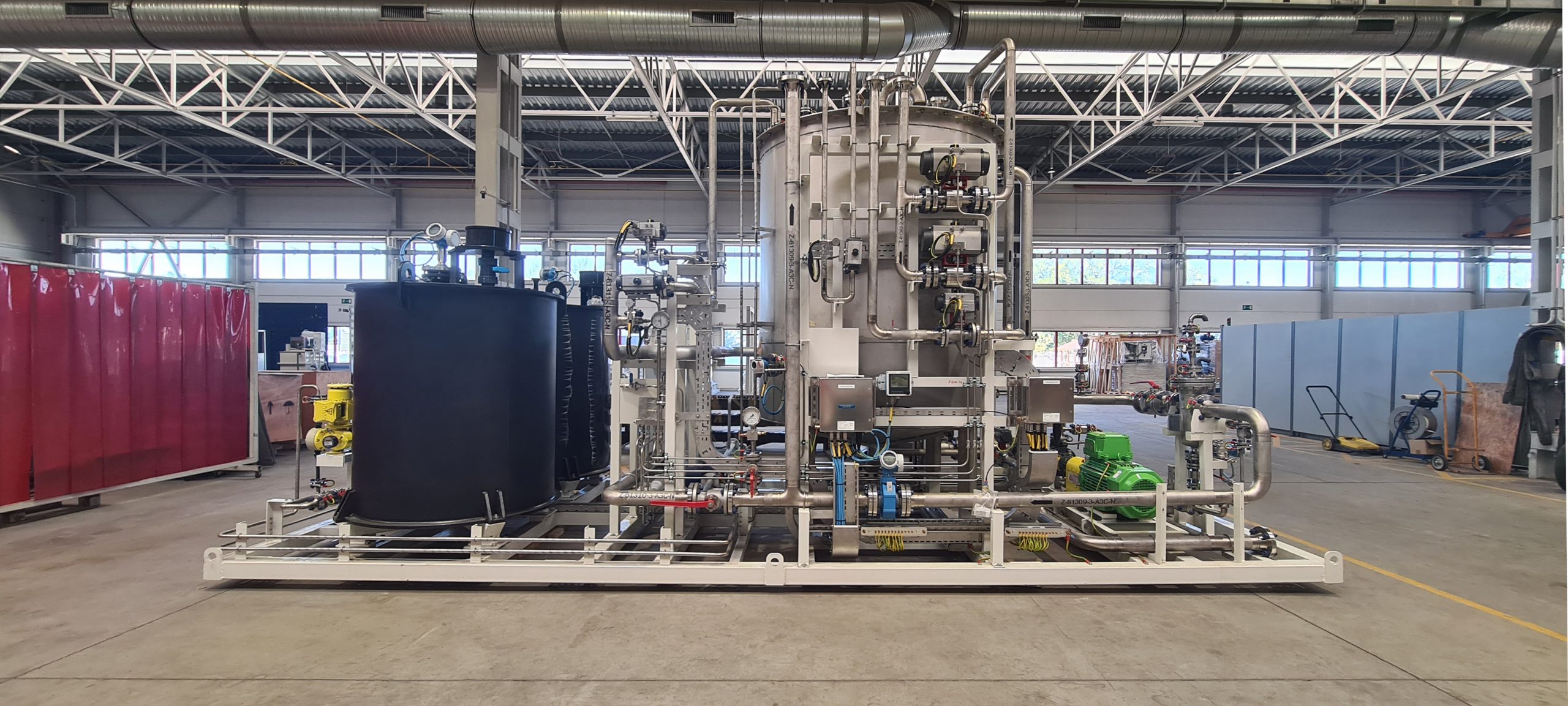

In 2022, we completed a very interesting and demanding project for the Petrochemical Industry – a closed acid recovery system based on reverse osmosis membranes for the polypropylene production plant.

The membrane concentration of acetic acid is a very complicated process. In the past, the industry used a distillation process to concentrate acids, but due to the very high energy consumption, we developed a membrane-based system for the client, which drastically decreased operating costs. The entire process was tested and improved in laboratory to validate the efficiency of the technology thus giving Esmil Process System, which is a part of Esmil Group, an exclusive know-how for this process.

Membrane concentration units are exceptionally complicated systems, each of which has several thousand different parts – pipes, pumps, valves, flow meters etc. All these elements must comply with the highest quality standards and correspond to ASME standards, which are used for the most hazardous industries, such Oil and Gas industry. During fabrication, we had to perform countless tests like non-destructive methods (NDT) including radiographic testing (RT), positive metal identification (PMI) and numerous other tests including even checking the quality and thickness of the paint!

Fabrication, assembly and testing of membrane complexes is carried out according to quality control procedures (QC/QA) in accordance with the developed inspection and test plans (ITP) under the supervision of the general contractor of the entire project.

The main task the treatment plant of 40-160 m3/h flow rate must cope with is to create a full acid cycle in the polypropylene production process. During the process, acetic acid with 12% concentration is used. The acid concentration in wastewater drops down to 2-3% so it’s fed to a membrane system to recover it back to the required 12%. Concentrated acetic acid returns to the production process, and the recovered water can be used both in the production process and for technical purposes.