In April 2023 Esmil carried out the pilot study to prove an innovative membrane-based solution to treat landfill leachate from the site near Glasgow in Scotland. The customer, specialised in operating landfill leachate sites, was looking for a cost-effective solution to bring down off-site tankering costs. The site presently has NO treatment facility, high chemical oxygen demand (COD) and ammonia leachate is tankered off-site costing the site huge money.

The objective of the site pilot study was to treat the leachate to separate ammonia and achieve < 10 mg/l ammonia concentration in the treated leachate stream using the double pass reverse osmosis (RO) membrane system. Followed by a successive lab pilot study at the High Wycombe Facility, Esmil proposed a combination treatment program using a special Media Filtration-based pre-treatment and membrane system as a robust solution to ensure compliance going forward, as well as an operating buffer for future environmental constraints. Key parameters for this site pilot evaluation include:

- Separation of organics and ammonia.

- Producing the treated water suitable for the discharge to watercourse to reduce the transportation cost.

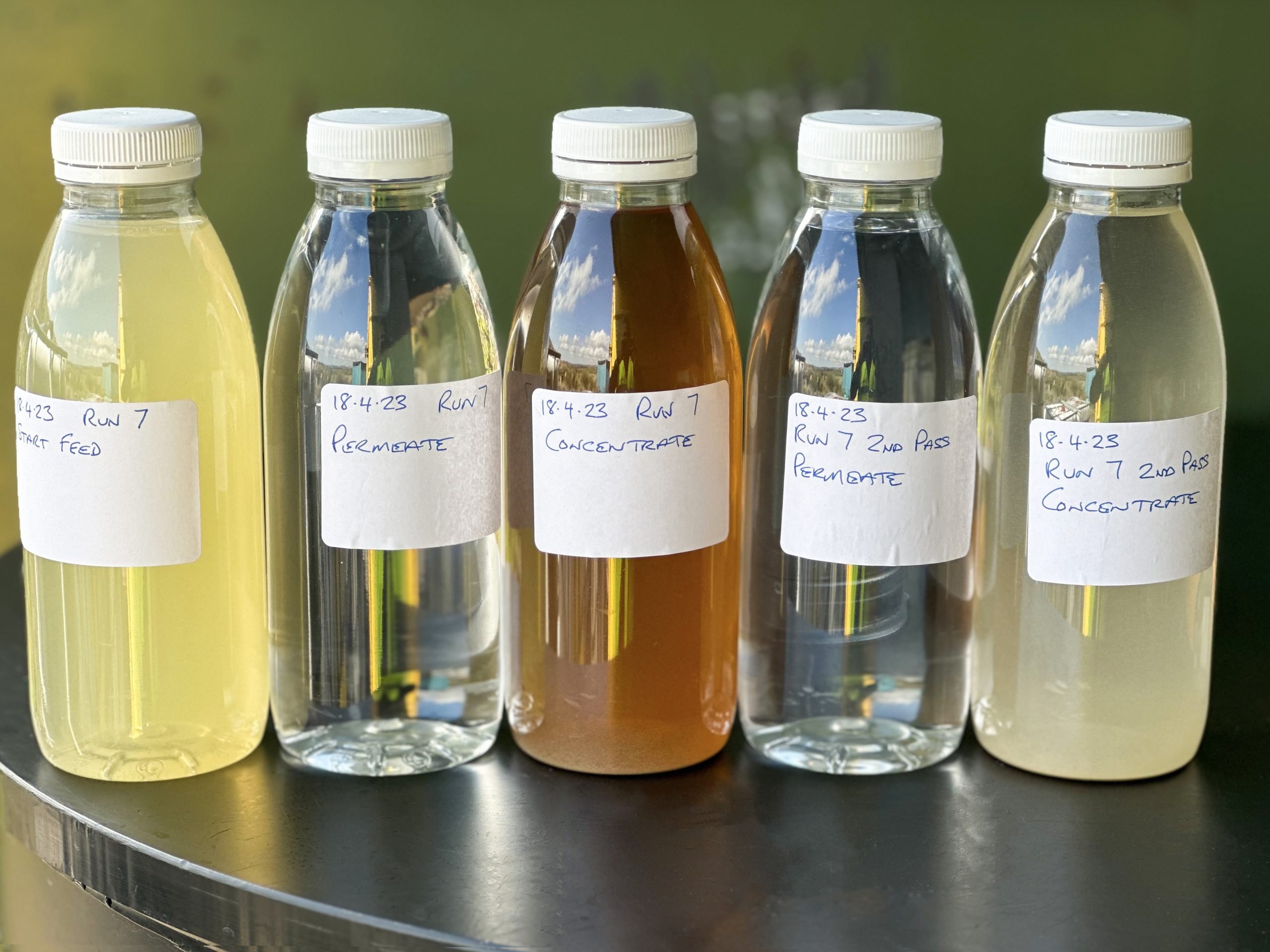

The process involved a double-pass membrane system, with the first pass to grossly reduce organics and ammonia. The second pass acts as the polishing stage by treating the first pass permeate to ensure the desired water quality for discharge. The concentrate from the second pass is recycled to minimise the waste (membrane concentrate) volume.

The pilot study result suggests that the treated water with ammonia concentrations below 10 mg/l and COD levels below 100 mg/l are achieved, meeting the desired quality standards. The hydraulic recovery in the range of 80 -85% shows that the present off-site tankering volume can be reduced by 80% making the treatment process very attractive to the customer. Additionally, the RO membranes flux (treated water producing capacity measured in litres per square meter surface area per hour) remains unaffected, indicating the feed didn’t irreversibly block the membranes.

The pilot test successfully demonstrated the effectiveness of Esmil’s solution in significantly reducing ammonia, COD and total dissolved solids (TDS) levels in the treated water. Esmil’s rich experience, in-house know-how regarding the membrane selection and operating process parameters for such applications played a vital role in the success of this pilot study. Esmil Group is proud to help landfill leachate facility to find suitable cost-effective solution to their waste handling issue.