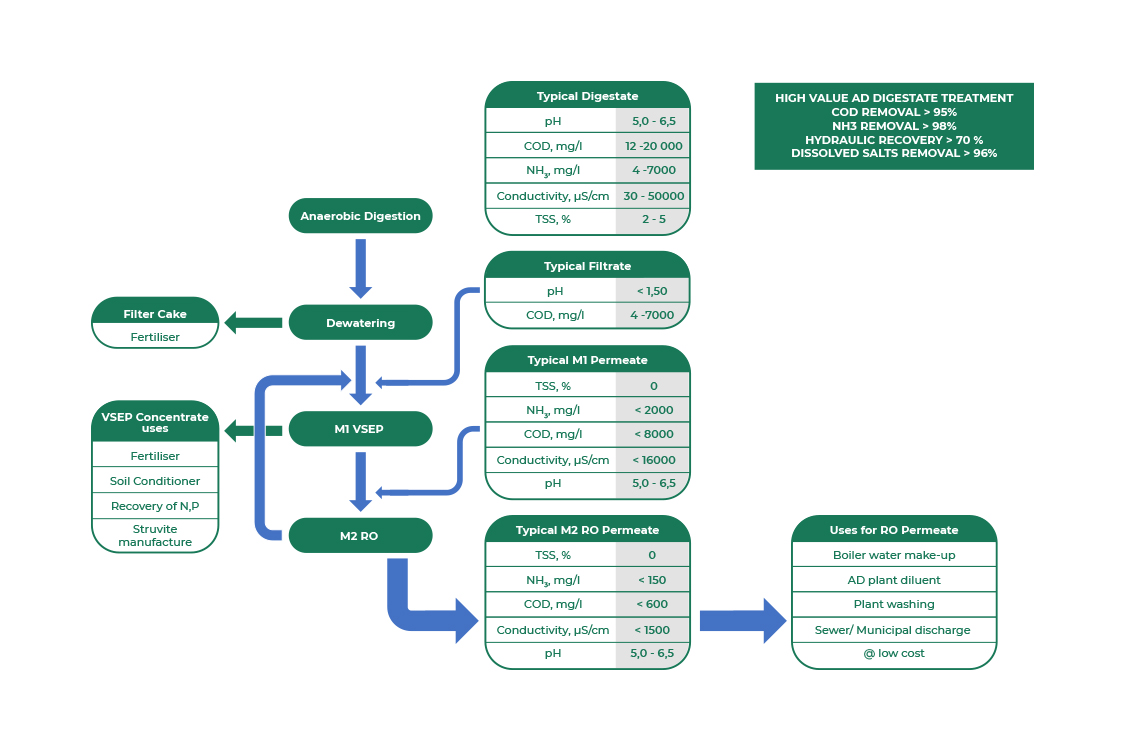

The first stage of digestate treatment is digestate dewatering utilising a Multidisc Screw Press Dehydrator (MDQ) which produces a dry cake of up to 40% (DS). This stackable filter cake is typically sold as fertiliser. The recovered filtrate is then processed in the first stage of membrane treatment. This first stage is defined by the quality of the recovered filtrate.

The unique patented VSEP technology (Vibratory Shear Enhanced Processing) is used to process foul, high solids filtrates which cannot be efficiently processed by standard membrane types. VSEP technology applied as the first membrane stage reduces the risk of fouling and water recovery in this stage is expected to realise hydraulic recovery in the region of 65-80%. Significant strip of feed COD, TSS and NH3 is achieved at this first stage yielding a concentrate with significant economic potential.

The VSEP concentrate stream is traditionally used as a concentrated liquid soil conditioner or fertiliser. ESMIL’s high value digestate treatment system recognises that this concentrate has significant economic potential in the recovery of N and P in concentrated forms or by complexing out struvite (long release inorganic fertiliser) through the addition of magnesium salts.

The final stage of digestate treatment is reverse osmosis or hyperfiltration. RO treatment polishes the permeate recovered from the VSEP units to final client requirements or specification. It is ESMIL’s experience that over 99% of ammonia (NH3), and soluble COD can be achieved over 2 stages of RO membrane treatment.

The resultant high quality RO permeate may be used for:

- Anaerobic digester feed dilution;

- Plant washing / cleaning operations;

- Boiler feed make-up (may require additional polishing);

- Discharge to sewer at low cost.

Whereas the resultant RO concentrate streams are cycled back into the VSEP feed.