From the 1960’s the dairy industry has used membrane technologies to improve product quality, increase process efficiencies and achieve advanced molecular concentration and separation. The dairy industry is now the second largest consumer of membrane technologies (after waste water treatment) world-wide.

ESMIL design, engineer, construct and instal specialised membrane systems to cater for the four major value chains in the dairy industry:

- Isolation and concentration of both milk and whey products

- Isolation and concentration of lactose and proteins

- Milk and brine stabilisation and clarification

- Permeate recovery for re-use

Different membrane application techniques are utilised to meet customer requirements as depicted in Table below.

Typical Dairy Industry Membrane System Applications

| Membrane Type | Molecular Cut-off | Principle of Operation | Dairy Application |

|---|---|---|---|

| Microfiltration | > 200 kDa | LP (< 2,0 bar) | Skim milk Dextrose Clarification Bacterial removal |

| Ultrafiltration | 1 – 200 kDa | MP (< 10 bar) | Milk standardisation Reduction of Ca, lactose Concentration of whey, protein & milk |

| Nanofiltration | 300 – 1 kDa | MP (5 – 40 bar) | De-brining of whey Lactose isolation |

| Reverse Osmosis | 100 Da | HP (10 – 100 bar) | Volume reduction Water recovery Solids concentration |

ESMIL are able to combine technologies along with membrane systems to provide value added results to the system design. ESMIL incorporate Ion Exchange, Electrodialysis and VSEP technologies to enable efficient treatment of the perennially troublesome streams in the dairy processing industry. These include:

- Treatment of brine streams

- Treatment of acid whey and lactose mother liquor streams

- Treatment of cream & protein by-product streams

- Fat recovery

- Waste water treatment & volume reduction

ESMIL thus provide the customer with a platform to interrogate different process synergies and discover opportunities through the use of combinative technologies and experience. ESMIL remain at the forefront of cutting-edge technologies needed to extract maximum process efficiencies in the entire dairy process value chain.

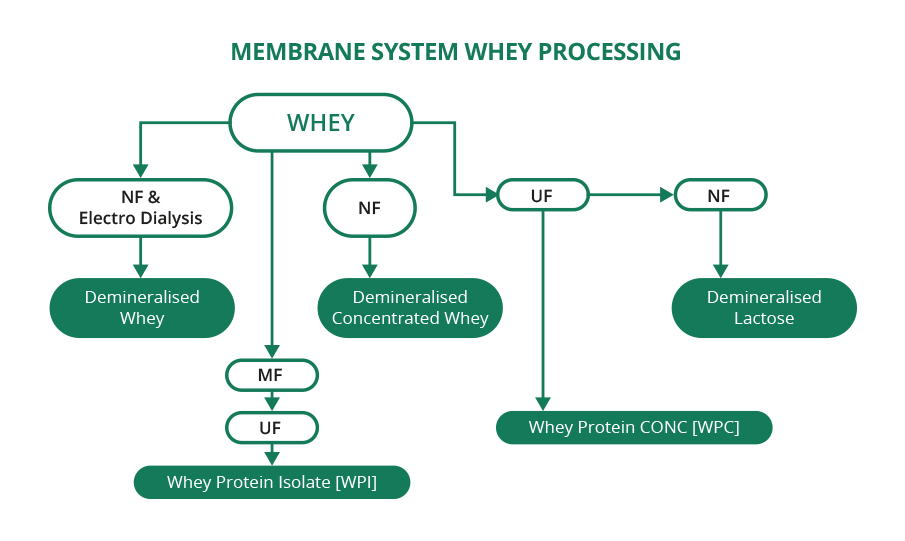

The whey processing value chain represents one of the largest areas of waste and opportunity in the dairy industry. Traditional treatments of whey (low pH, high temp) caused the degradation of the proteins and sugars in this stream. Membrane systems allow the recovery of proteins and sugars using a number of techniques as illustrated in Figure 1.

Figure 1 – Membrane system whey processing

There are many benefits of the application of these technologies to dairy producers (and the final consumer)

- Producers get better pricing

- Reduced hauling costs

- Value added milk products

- More consistent product all year round

- Improved plant efficiency and lower unit costs

- Less whey to dispose, reduced effluent costs

Case History ~ Treatment of Dairy Plant Effluent

Typically, a number of standard dairy plant effluent streams are processed with membrane systems to improve the final water quality and effect the re-use of milk components.

- Rennet casein precipitate wash water is treated with NF to recover casein solids

- Cheese brines are treated using MF/UF to reduce bacterial load without affecting the chemical composition or the organo-leptic qualities of the brine

- White, flush and pre-rinse waters are treated with a combination of UF/NF/RO treatments dependant on final water specifications. Solids recovered in the retentates of these processes are either recycled back into the process, or used as a component of animal feeds

- Acidic & alkaline CIP streams can be regenerated normally with NF or UF membrane systems

Case History ~ Extraction & isolation of whey proteins

Development of membrane processes to isolate and recover milk and whey proteins has been utilised since 1980. Improvements in membrane design and membrane surface polarisation properties now allow the producer the ability to recover more precisely various protein molecules.

Of specific interest, is the recovery and separation of α and β lactoglobulin proteins from whey using UF membrane processes (WPI). These proteins are used in the manufacture of high value add downstream products (infant milk formulae, protein hydrolysates for the food industry).